Capabilities & Resources

The COE. Adv. Mat. Eng. Is formed by material scientists, engineers, theoretical scientists, physicists and chemists. It provides professional service to the inertial fusion, magnetic confinement, and electromechanical divisions at General Atomics.

Capabilities

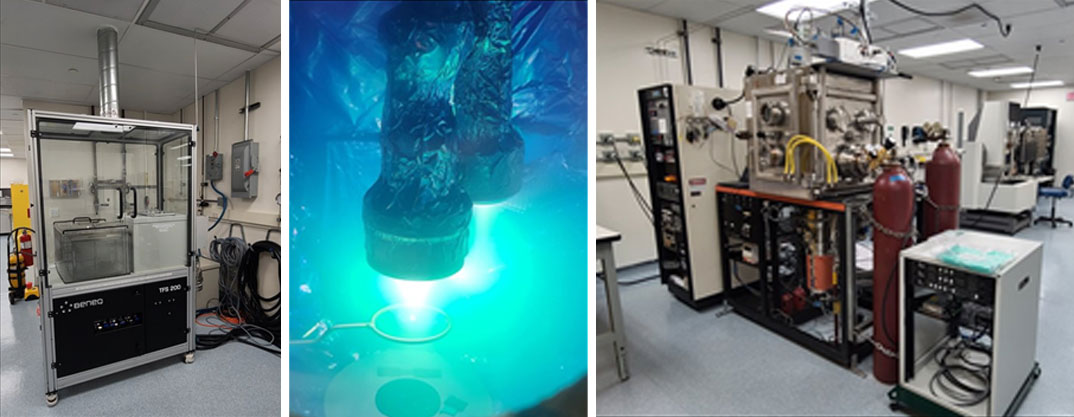

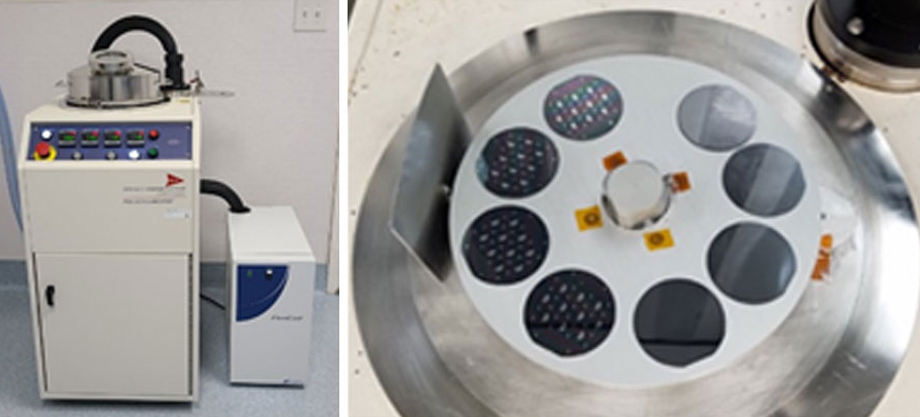

- 4 Sputter coaters with DC, RF, HIPIMS, Pulsed DC capabilities

- Atomic Layer Deposition

- Electron Beam Deposition chamber

- Large sample ( 1foot x 1foot) sputter – ultra-smooth optical quality coatings

- Parylene coformal coater

- Hollow cathode coater for Diamond-like-carbon amorphous coatings

Coating Capabilities

- Photolitography mask aligner

- Photolitography writter (in service in June 2022)

Cleanroom Facilities

- Onsite high-performance computing

- Scientific software access and development

- Quantum hardware access

- National computing facility access (ex. NERSC)

Computing

- SEM-EDS

- Filmetrics – optical profiloeter

- Nexiv- Automated inspection - Confocal Microscope

- X-ray transmission and X-radia equipment

Metrology

- Electrochemical system for the synthesis of nanoporous templates

- Electrochemical deposition of metals

- Supercritical point drier

- Thermal treatment oven

- Heated press

Nanofabrication Lab

- Ab-initio methods (ex. post-Hartree Fock)

- Density functional theory, Tight-binding

- Molecular Dynamics

- Kinetic Monte-Carlo and mesoscale dynamics

- CALPHAD and phase-field methods

- Macroscopic materials modeling (ex. FEM)

Modeling and Simulation

Resources

Collective Capabilities

In-House Capabilities Experience

| Types of Coatings | Wavelength Domains | Deposition Techniques | Materials | Substrates | Size | Environmental Durability | Quality Specs | Metrology | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Antireflective (AR) | Transparent conductors | UV (<400nm) | ALD | Oxides | Ytterbium Fluoride | Polycarbonate | < 1" | Adhesion | MIL-C 497 | UV-VIS |

| High reflective (HR) | Sculptured / Metamaterials | VIS (400-700nm) | CVD | Fluorides | Yttrium Fluoride | Crystalline | < 5" | Moderate Abrasion | MIL-PRF-13830B | FTIR |

| Partial reflective (PR) | Bandpasses | NIR (700-1400nm) | Roll Coating | Metals | Lanthanum Fluoride | Metallic | < 10" | Severe Abrasion | ASI9100 | Cavity Ringdown |

| Rugate | Dichroics | SWIR (1.4-3.0um) | Thermal Evaporation | Semiconductors | Silver | Semiconductor | < 30" | Salt-fog spray | SEM / EDAX | |

| Notch | Beamsplitters | MWIR (3um-8um) | E-beam PVD | Polymers | Gold | Fluorides | > 30" | Salt-fog Immersion | Raman | |

| Multiple Notch | High laser-damage threshold (LDT) | LWIR (8-14um) | Ion-assisted (IAD) e-beam PVD | Nitrides | Chrome | Glasses (all types) | Boiling-water Tests | Dosimetry | ||

| Hard Coatings | DC Sputtering | Silicon dioxide | Titanium dioxide | Proprietary Durability Tests | ||||||

| Magnetron sputtering | Magnesium Fluoride | Nickel | ||||||||

| Ion-beam sputtering (IBS) | Cerium Flouroide | Tantalum | ||||||||

| Diamond-like coating (DLC) | Praseodymium Fluoride | Tungsten | ||||||||

| High-power Impulse | Hafnium Oxide | Aluminum | ||||||||

| Magnetron Sputtering (HiPIMS) | Tantalum Pentoxide | Platinum | ||||||||

| Titanium Dioxide | Palladium | |||||||||

| Zirconium Oxide | Indium Tin Oxide | |||||||||

| IRG24/26 Chalcogenides | Parylene-C, N | |||||||||