Electromagnetic Systems Group

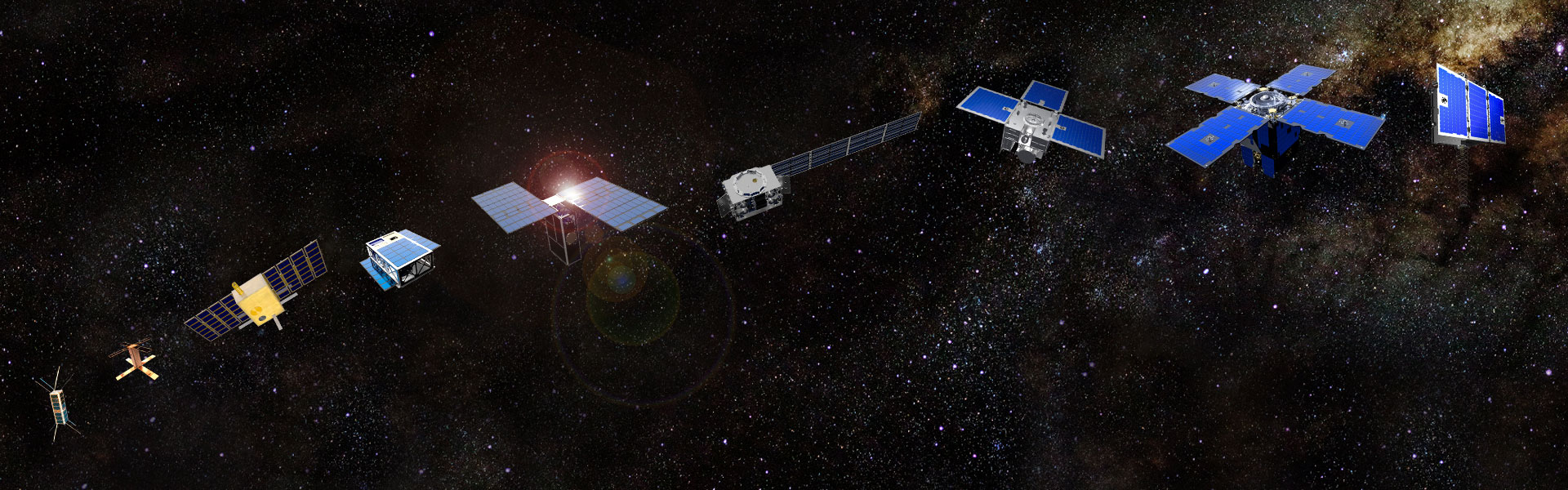

General Atomics Electromagnetic Systems Group (GA-EMS) is applying its rich heritage in research, science, and technology innovation to develop and deliver multi-mission systems and first-of-kind products to help defend our national interests and support critical commercial enterprises worldwide.