TRIGA Complete Control Systems

All types of research reactors can be operated with this multipurpose control and instrumentation system. A state-of-the-art instrumentation and control system using microprocessor technology provides replacement of older, existing instrumentation and control systems that contain obsolete components. Our features include:

- Eliminates most manual data logging

- Provides automatic or manual reactor operation modes

- Provides complete real-time operator display

- Replays historical operating data on monitor or printer

- Meets all applicable NRC and IEE specifications

Here's How Our System Works

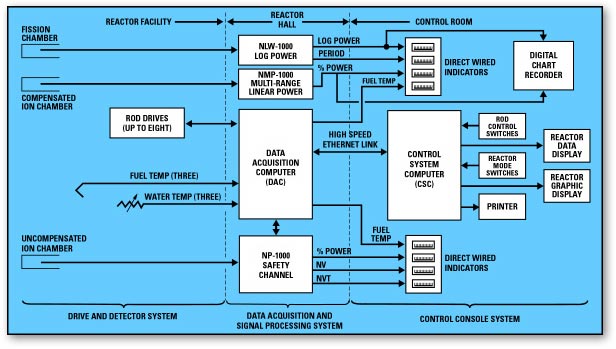

The complete system consists of three major subsystems:

- Control Rod Drive and Detector System

- Data Acquisition and Signal Processing System

- Control Console System

The Data Acquisition and Signal Processing System and Control Console System each have independent computers (DAC and CSC) for monitoring and control purposes. The Data Acquisition and Signal Processing System may include the NLW-1000 and NMP-1000 nuclear instruments and the related reactor safety scram and shutdown circuits.  All these systems are mounted in an auxiliary instrumentation cabinet, which is located in the reactor hall, usually near the reactor. Thus, even if the Control Console System is disconnected, the Data Acquisition and Signal Processing System can control or shutdown the reactor in a safe manner.

All these systems are mounted in an auxiliary instrumentation cabinet, which is located in the reactor hall, usually near the reactor. Thus, even if the Control Console System is disconnected, the Data Acquisition and Signal Processing System can control or shutdown the reactor in a safe manner.

Information on all aspects of reactor operation is displayed on the Control Console System. The two-color graphics monitors can display real-time operations data in concise, accurate and easily understood formats. Bar graph indicators and visual and audible annunciators are also provided. Information displayed on the two monitors can be recorded on hard copy using the graphics printer in the Control Console System. The DAC collects data during reactor operations and stores it in a historical database. Reactor operations can then be replayed in real-time or slow motion. This record is a powerful tool that can be used for operations review and maintenance troubleshooting.

Reactor control rod position commands are transmitted via a high-speed Ethernet link from the Control Console System to the Data Acquisition and Signal Processing System and in turn to the rod drive mechanisms. This reduces the complexity, vulnerability, and cost of data transfer. The Data Acquisition and Signal Processing System computer controls rod positions using integral software during automatic mode operation.

Safety Features

The two independent, redundant percent power safety instruments are provided to ensure safe operation of the reactor. Both instruments are designed to meet all applicable specifications and both instruments also have automatic pre-startup on-line self-diagnostic/testing and calibration verification with data display and documentation printout. Both instruments also have isolated outputs for display and safety scram circuit inputs. Redundancy and diverse designs ensure against reactor instrumentation and control system common mode failure. Backup bar graph displays and safety/scram circuits are also hardwired to instrument outputs.

Data Display and Storage

Two color monitors provide real-time information: one shows reactor operations graphics and the other displays important operating parameters. Hard copies of the two displays can be made using the graphics printer.