Medical Isotopes

General Atomics Electromagnetic Systems (GA-EMS) has a long history of leveraging advanced research for medical applications ranging from magnetic resonance imaging to sterilization technology. GA-EMS is now working toward advancing the state of the art in nuclear medicine and ensuring physicians and hospitals continue to have a safe, reliable source of medical radioisotopes.

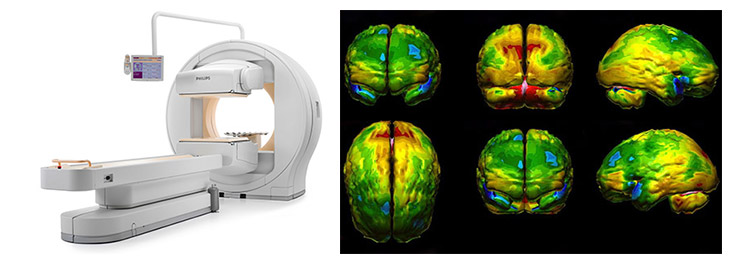

More than 40 million nuclear medicine procedures are performed each year, and the large majority of them depend on a single isotope: Technetium-99m (Tc-99m). Tc-99m is a vital component of single-photon emission computed tomography (SPECT), which physicians rely on for a wide variety of diagnostic procedures, such as cardiac, brain, and kidney scans. Tc-99m is produced on-site in hospitals and other medical facilities from radioactive decay of Molybdenum-99 (Mo-99), which is a short-lived fission product of Uranium-235.

Because of their short half-lives, neither Tc-99m nor Mo-99 can be stockpiled, and the nuclear medicine industry requires a continually operating Mo-99 supply chain to meet its needs. Currently, nearly all Mo-99 used in nuclear medicine is manufactured in a few aging reactors that are beginning to reach their end-of-life and shut down. Worse, this manufacturing process requires highly enriched uranium (HEU), which raises concerns of nuclear proliferation.

GA-EMS has developed a unique proprietary method, selective gaseous extraction (SGE), that extracts Mo-99 of the highest specific activity without requiring HEU and without generating liquid uranium processing waste, a significant problem with current approaches. The SGE process, an outgrowth of GA-EMS' decades of work on gas-cooled reactors, is a proven technology that requires no new infrastructure and will work efficiently with existing Mo-99 distribution.