Coatings

The targets, hohlraums, and other components that General Atomics manufactures for its clients often include very thin layers of various elements and compounds. To meet this need, GA employs several different thin-film deposition techniques.

Atomic Layer Deposition is a form of chemical vapor deposition in which a thin film is deposited as a result of interactions between chemical precursors and a substrate. ALD offers excellent control and the possibility of films as thin as a single layer. However, the precursors that can be used for ALD are limited, and film growth is very slow.

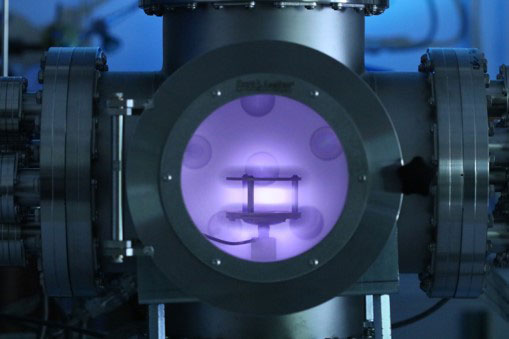

Physical Vapor Deposition involves the creation of a vapor phase in a vacuum from a target composed of the desired film material, which then condenses as a film on the substrate. The two most common methods for creating the vapor phase are evaporation and sputtering. Sputter coating uses a plasma discharge to bombard the target, while in evaporative coating, the vapor is created by either resistance heating or an electron beam.

Evaporative methods allow for the highest deposition rates and high film purity. However, the process uses extremely high temperatures, which limits the types of films and substrates that can be used. Control is poor, and coverage can be suboptimal.

Sputter coating allows the creation of a wide variety of coatings, including ceramics and exotic alloys. Film control is good, and some variation in substrate geometry is possible. However, deposition rates are fairly slow (though faster than ALD), and the equipment set-up required for film production is complicated.

Sputter coating is the primary method used by GA IFT in manufacturing targets. We can deposit thin films on a variety of cylindrical geometries as well as substrates with rippled surfaces. Very often the manufacturing process involves multiple steps and micromachining between layer deposition runs. In situ thickness monitors are used to maintain layer precision.

GA has several decades of experience and innovation in thin film coating techniques, and we regularly customize approaches to meet unusual customer requirements.