ITER Manufacturing

General Atomics is fabricating waveguides, diagnostics, and the world's most powerful pulsed superconducting electromagnet for the international ITER experiment, an unprecedented scientific collaboration of 35 nations that will prove the feasibility of fusion – the process that powers the stars – to produce virtually limitless safe, clean and renewable energy.

The Central Solenoid is the heart of ITER, and the 5-story, 1,000-ton magnet will drive 15 million amperes of electrical current in ITER's fusion plasma for stabilization. Each coil is 7 feet tall, 14 feet wide, and is composed of 3.5 miles of superconducting cable. The completed Central Solenoid is a critical component for ITER.

GA is developing a range of other technologies for ITER. These include:

- ITER ECH waveguide manufacturing processes

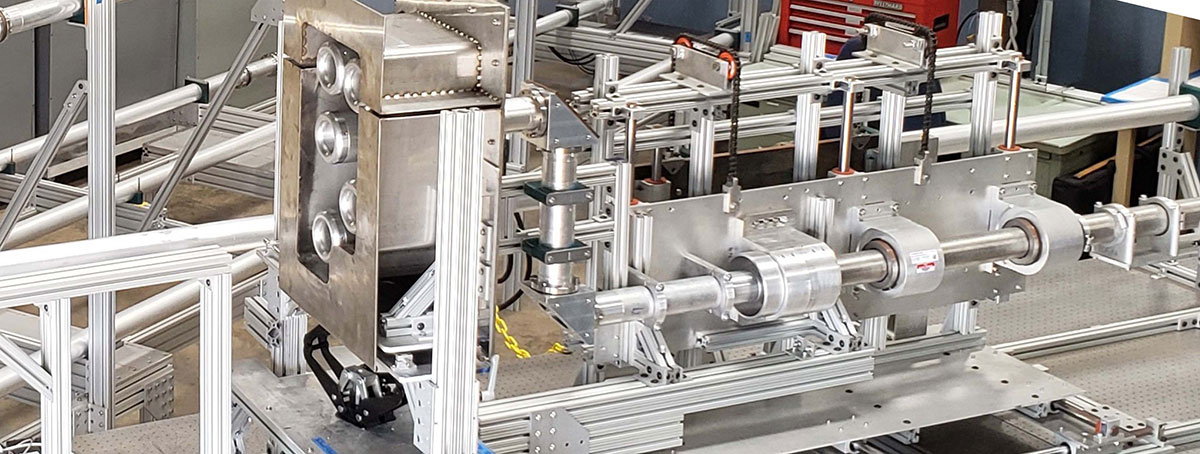

- ITER ECH polarizer design and manufacturing

- Methods to prevent uncontrolled collapse of ITER plasmas and high energy bursts from plasma edge using internal stabilization coils

- Low Field Side Reflectometer (below): A diagnostic using microwaves to measure plasma density profiles

- Wide Angle Visible & Infrared Viewing System: Set of diagnostic cameras to monitor for hot spots in ITER plasma chamber

- Toroidal Interferometer Polarimeter: Diagnostic to measure plasma density distribution

- Archiving methods for storing multi-gigabytes of ITER experimental data