DIII-D Facility Adds Tool to Resolve Heat Handling in Future Fusion Power Plants

New approach will test advanced metal divertor configurations

San Diego, April 25 – Researchers at the DIII-D National Fusion Facility are preparing to test a new method to enable future fusion power plants to withstand the fierce conditions of heat and particle flow created by the fusion reaction. Solutions such as this will be critical to developing practical fusion energy.

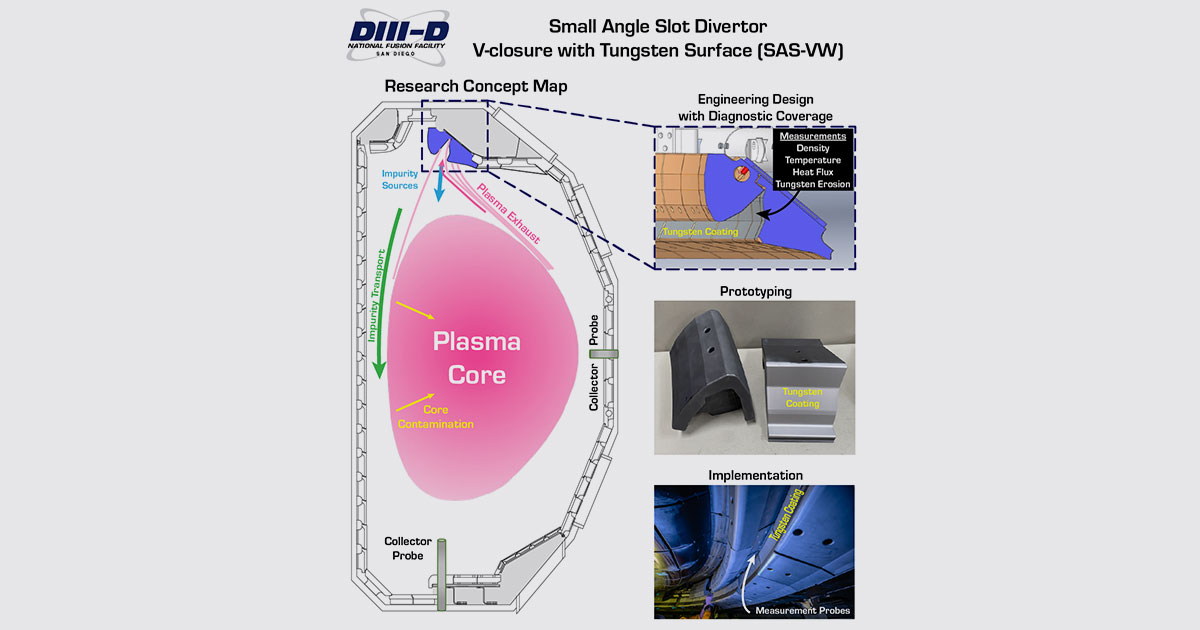

Current fusion power plant designs envision using tungsten as a key component in the reactor vessels because of its high resistance to heat and radiation. However, tungsten is also an impurity for the fusion reaction and can impair performance. The new approach researchers are testing will leverage an existing component on DIII-D, known as the Small Angle Slot (SAS) Divertor, to minimize tungsten erosion and release into the plasma.

“Developing robust wall materials is absolutely necessary for economic fusion energy,” said Dan Thomas, Ph.D., a scientific manager at DIII-D who is helping to coordinate the multi-institution effort on these new experiments. “The specific way in which this will be accomplished is still an open unsolved question and a very active area of research worldwide. Here at DIII-D, we have an active collaboration, with multiple institutions looking at the many ways plasma and the vessel wall can interact.”

DIII-D is the largest magnetic fusion research facility in the United States and is operated by General Atomics for the U.S. Department of Energy Office of Science. The heart of the facility is a tokamak that uses powerful electromagnets to produce a doughnut-shaped magnetic bottle for confining a fusion plasma. Plasma is the fourth state of matter in which electrons are stripped from the atoms, producing a highly ionized “soup” of nuclei and electrons that can be controlled by magnetic fields. In DIII-D, plasma temperatures that are 10 times hotter than the Sun are routinely achieved. At such extremely high temperatures, hydrogen isotopes fuse together and release energy.

However, plasma particles and their associated heat eventually leak through the tokamak’s magnetic fields. For this reason, tokamaks incorporate a device called a divertor that removes these stray particles from the edge regions of the plasma. The heat and particle flow along the magnetic field lines in the edge region is intense enough to damage the inside surfaces of the tokamak, as heat levels can exceed those found in a rocket engine nozzle.

Fusion researchers view tungsten (atomic symbol W) as the leading candidate to withstand these conditions, but it comes with a significant concern. Wall surfaces exposed to the fusion reaction can erode and form impurities in the plasma. Suppression of tungsten leakage from the divertor into the core of the reactor is especially important for efficient fusion performance.

Tungsten contamination of even 0.001% in the fusion fuel is enough to seriously impair performance. Thus, methods of reducing tungsten erosion in the divertor and preventing its escape from the divertor region are critically important for future designs.

The SAS-VW (V-closure with Tungsten Surface) experiment employs a row of tungsten-coated tiles in the divertor to study these issues. The original SAS divertor design demonstrated the beneficial aspects of improved divertor geometry for better heat dissipation and decreased impurity leakage. Building on this success, and using a unique set of diagnostic instruments and detailed modeling, SAS-VW is designed with improved shape to address three research questions in an uncontaminated plasma environment.

During the experiment, researchers will examine how tungsten emerges from such a divertor, how it moves towards the core, and how it affects core fusion performance. These studies can be used to find solutions with a high-performance fusion core, enabling DIII-D to develop integrated solutions for fusion power plants. The scientific understanding gained from these experiments will support designs and simulations for the next generation of fusion devices.

“Our aim here is to solve a critical challenge to economic fusion energy,” Thomas said. “This is another illustration of the flexibility and impact of the DIII-D research program.”

About General Atomics

Since the dawn of the atomic age, General Atomics innovations have advanced the state of the art across the full spectrum of science and technology – from nuclear energy and defense to medicine and high-performance computing. Behind a talented global team of scientists, engineers, and professionals, GA’s unique experience and capabilities continue to deliver safe, sustainable, economical, and innovative solutions to meet growing global demands.

About the DIII-D National Fusion Facility.

DIII-D is the largest magnetic fusion research facility in the U.S. and has been the site of numerous pioneering contributions to the development of fusion energy science. DIII-D continues the drive toward practical fusion energy with critical research conducted in collaboration with more than 600 scientists representing over 100 institutions worldwide. As a U.S. Department of Energy, Office of Science User Facility, participation in DIII-D research is open to all interested parties. For more information, visit www.ga.com/diii-d

For more information contact:

Zabrina Johal

Senior Director of Strategic Development

858-455-4004

Zabrina.Johal@ga.com