Fabrication

General Atomics has supported the Department of Energy's Inertial Confinement Fusion (ICF) program since 1975. GA researchers pioneered work on the conceptual design of inertial fusion energy power plants, and our early efforts with Lawrence Livermore National Laboratory led to the design of a laser-driven power plant called Cascade, which demonstrated the theoretical possibilities of inertial fusion.

GA began supplying the ICF Program with targets, target systems, and target support services in 1990. Today, GA supplies more than 10,000 such components every year for experiments at the five U.S. ICF laboratories.

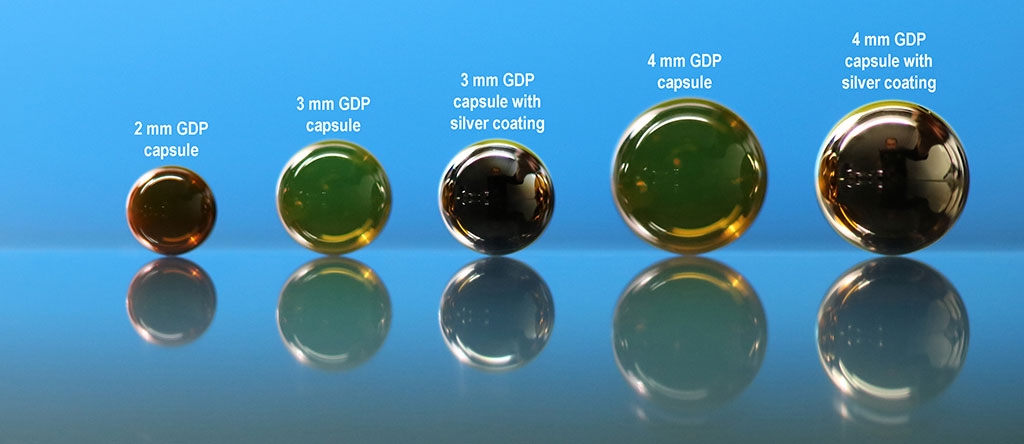

These targets and components are produced by a combination of highly precise micromachining and chemical processes such as electroplating and physical vapor deposition. Polymer, glass, and beryllium microshells filled with hydrogen gas are currently the main types of target capsules in the ICF program, though other geometries are also produced.

Shell targets typically range from around 0.5 mm to 5 mm in diameter, and they can have a wide variety of physical and chemical characteristics. Polymer shells can range from full density to ultra-low density foams, with wall thicknesses that vary from a few to several hundred micrometers. The shell walls are not necessarily homogenous; they can consist of multiple layers that can be doped with a variety of elements. Permeability can be controlled with specific types of coatings.

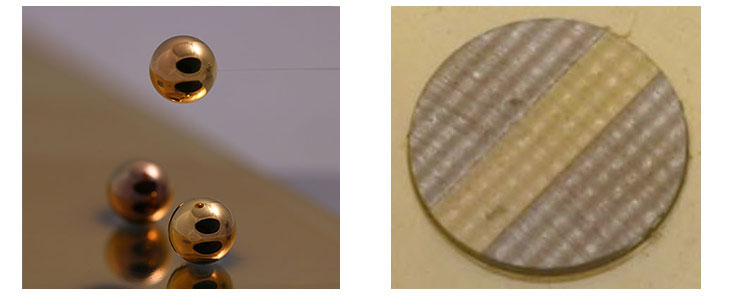

Planar targets can include layers of polymers, foams, metals, oxides, salts, and other materials. Some targets have patterns imposed on them, such as sine waves of various amplitudes and wavelengths, square waves, and two-dimensional sine waves. Planar targets are generally mounted on a frame.

A variety of foams can be fabricated for targets with several types of polymers, some with submicron cell sizes. The foams can be cast or machined into custom shapes and may include an embedded capsule.

In addition to targets, GA also manufactures hohlraums, the cylindrical containers that hold the ICF target fuel capsule. These can be of uniform lead or uranium composition or multi-element "cocktails". A typical multilayered coating consists of repeated nm-scale multi-layers. For uranium hohlraums, several microns of gold are sputtered onto the uranium coating to protect it from oxidation. We have also produced hohlraums with foam inserts.

GA also produces custom-built and modified equipment used for target fabrication and target handling and continually responds to needs for unique target fabrication equipment by designing and building new systems. These include glow discharge polymer (GDP) coating systems for CH and doped CH coatings, spheremappers and wallmappers for measuring surface finishes and wall thickness of capsules, and assembly/characterization stations for cryogenic target systems.