Microfabrication

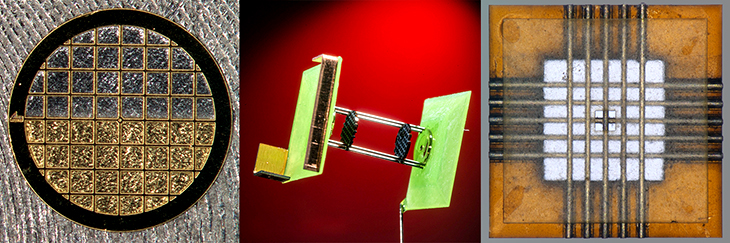

General Atomics can supply high-precision micro-machined components on a production or development basis. We can produce millimeter and sub-millimeter-sized components of different shapes in a variety of materials. We have an array of sophisticated and customized automated and robotic assembly stations that can rapidly produce large quantities of high-precision components. We employ machine learning, machine vision, and force-feedback approaches.

For tasks unsuited for robotic assembly, we also have a suite of versatile and accurate manual assembly stations at which our highly skilled and experienced technicians can produce made-to-order components for a variety of applications. Our production processes integrate our industry-leading metrology capabilities to ensure adherence to the most exacting customer requirements.

The videos below illustrate some of GA’s precision microfabrication capabilities.

This video illustrates robotic gluing and assembly of 100 µm-diameter gold dots on a high-density carbon substrate, subsequently laser machined into a diagnostic component installed on a National Ignition Facility hohlraum.

Another example of robotic gluing and assembly of thermal-mechanical packages for the National Ignition Facility.

The GA IFT division regularly develops new fabrication techniques to meet exacting customer requirements. For more information on our capabilities, contact the representative listed at left.